Steel pipes for water and gas transmission, such as buried pipes, usually need anti-corrosion treatment to prevent corrosion, and to prolong the service life of steel pipes. 3 Layer Polyethylene (3PE / 3LPE) and Fusion Bonded Epoxy (FBE) are widely used anti-corrosion treatment for steel pipes.

3PE anti-corrosion steel pipe is coated with Epoxy inside, adhesive layer middle, and outside with polyethylene layer.

FBE coating pipe is coated with Epoxy Coatings. So it is called Fusion Bonded Epoxy pipe.

3PE anti-corrosion steel pipe and FBE coating pipe are widely used in pipeline systems for the transmission of oil, gas, water and other fluids. 3PE anti-corrosion steel pipe and FBE coating pipe have high resistance to corrosive from chemicals, moisture, harmful environment, etc..

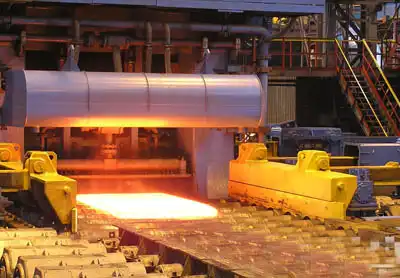

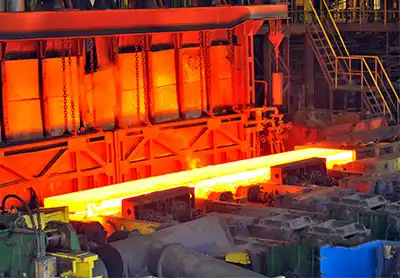

The base material of 3PE anti-corrosion steel pipe includes seamless steel pipe, spiral steel pipe and straight seam steel pipe. Three layer polyethylene (3PE / 3LPE) anticorrosive coating has been widely used in the oil pipeline industry for its good corrosion resistance, water vapor permeability resistance and mechanical properties.

Fusion Bonded Epoxy (FBE) is a thermosetting powder applied anti-corrosion coating. It provides excellent protection for small to large diameter pipelines at up to moderate operating temperatures. FBE coating pipe is usually buried in soil and under water between -40~85°C temperature.

3PE anti-corrosion steel pipe include 3 layers: The first layers is fusion bonded epoxy, whose thickness is larger than 100μm (FBE>100μm). The second layer is adhesive, whose effect is binding epoxy and PE layers (AD: 170~250μm). The third layers is PE layer, which is polyethylene with advantages of anti-water, electrical resistance and anti mechanical damage. Therefore, 3PE anti-corrosion steel pipe integrates the advantages of FBE and PE. The 3PE anti-corrosion steel pipe manufacturers can also make FBE coating pipe.