430 stainless steel is a universal steel with good corrosion resistance. Its thermal conductivity is better than austenite, its thermal expansion coefficient is smaller than austenite, its heat resistance is fatigue, titanium is added to stabilize elements, and its mechanical properties of welding seams are good. 430 Stainless steel for building decoration, fuel burner parts, household appliances, home appliance parts. 430F is steel with free cutting performance on 430 steel, mainly used for automatic lathes, bolts and nuts, etc. 430LX adds Ti or Nb to 430 steel, reduces C content, improves machining performance and welding performance, and is mainly used in hot water tank, heating water system, sanitary appliances, durable household appliances, bicycle flywheel, etc.

430 stainless steel Characteristic process

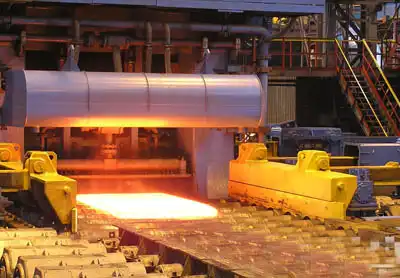

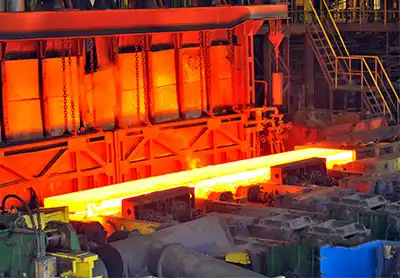

1D -- Surface with discontinuous granular shape, also known as fog surface. Processing technology: hot rolled + annealing shot peening + cold rolled + annealing pickling.

2D -- slightly shiny silver white. Processing technology: hot rolled + annealing shot peening + cold rolled + annealing pickling.

2B - Silver-white and better gloss and flatness than 2D surfaces. Processing technology: hot rolling + annealed shot peening + cold rolling + annealed pickling + tempered rolling.

BA - Excellent surface gloss, high reflectivity, like a mirror surface. Processing technology: hot rolling + annealing shot peening + cold rolling + annealing pickling + surface polishing + tempering rolling.

No.3 -- Good glossiness and coarse grain on the surface. Processing technology: polishing and quenching and tempering rolling with 100~120 grinding materials (JIS R6002) for 2D products or 2B products.

No.4 -- Good gloss and fine lines on the surface. Processing technology: polishing and quenching and tempering rolling with 150~180 abrasive materials (JIS R6002) for 2D products or 2B products.

HL -- Silvery gray with hair streaks. Processing: the 2D product or 2B product is polished with appropriate abrasive material to make the surface show continuous abrasive grain.

Process: 2D or 2B products are ground and polished to mirror effect with suitably sized abrasive materials.

430 stainless steel Chemical composition

Carbon (C) : ≤0.12%

Silicon (Si) : ≤0.75%

Manganese (Mn) : ≤1.00%

Phosphorus (P) : ≤0.040%

Sulfur (S) : ≤0.030%

Nickel (Ni) :≤0.60% (inclusive)

Chromium (Cr) : 16.00 ~ 18.00%

430 stainless steel Mechanical properties

Density: 7.75 g/cm&sup 3;

Melting point: 1427 ℃

Coefficient of expansion: mm/℃(at 20-100℃)

Young's modulus: kN/ MM&SUp 2;

Rigid modulus: kN/ MM&SUP 2;

Application Standard: N/A (UNS)

430 stainless steel Equivalent material

|

EN 10028-7/ EN10088-2 |

ASTM A240 |

JISG4304/4312 |

GB4237/4238 |

|

1.4016 |

430 |

SUS 430 |

1Cr17 |

If you need 430 stainless steel, please contact us!