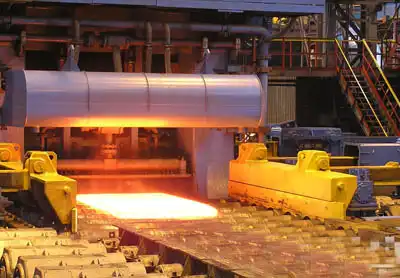

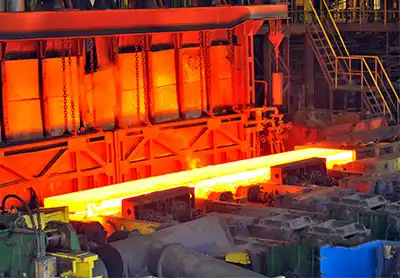

The 304L chromium-Nickel austenitic stainless steel is easy to be processed by forging, rolling, hot perforation and extrusion. The ingot heating temperature is 1150 ~ 1260℃, and the deformation temperature range is 900 ~ 1150℃. The steel containing copper, nitrogen and titanium and niobium stabilized depends on low temperature, while the high chromium and molybdenum steel depends on high temperature. Due to poor heat conduction, the heat preservation time should be longer. After hot working, the workpiece can be air-cooled.

304L Stainless Steel Chemical Composition

|

Chemical Element |

% Present |

|

Carbon (C) |

0.0 - 0.03 |

|

Chromium (Cr) |

17.50 - 19.50 |

|

Manganese (Mn) |

0.0 - 2.00 |

|

Silicon (Si) |

0.0 - 1.00 |

|

Phosphorous (P) |

0.0 - 0.05 |

|

Sulphur (S) |

0.0 - 0.03 |

|

Nickel (Ni) |

8.00 - 10.50 |

|

Nitrogen (N) |

0.0 - 0.11 |

|

Iron (Fe) |

Balance |

304L Stainless Steel Physical Property

|

Physical Property |

Value |

|

Density |

8.0 g/cm³ |

|

Melting Point |

1450 °C |

|

Thermal Expansion |

17.2 x10^-6 /K |

|

Modulus of Elasticity |

193 GPa |

|

Thermal Conductivity |

16.2 W/m.K |

|

Electrical Resistivity |

0.72 x10^-6 Ω .m |

Chromium-manganese austenitic stainless steel has a strong heat crack sensitivity, and the ingot should be slightly deformed and multipass, so the forgings should be stashed and cooled. Can be cold rolling, cold drawing and spinning and other cold processing technology and stamping, bending, winding and folding and other forming operations. 304L Chromium-Nickel austenitic stainless steel processing hardening tendency is weaker than chromium-manganese steel, after the first annealing cold deformation can reach 70% ~ 90%, but chromium-manganese austenitic stainless steel due to deformation resistance, the processing hardening tendency is strong, should increase the number of softening annealing. Generally, the intermediate softening annealing treatment is water cooling at 1050 ~ 1100℃.

Whether you need chromium nickel austenitic stainless steel or chromium manganese austenitic stainless steel, we can meet your requirements, if you have any questions, please feel free to contact us!