GB/T 8162 42CrMo seamless steel tube is widely used. 42CrMo seamless steel tube has a hollow section. It is widely used for conveying fluid, such as conveying oil, natural gas, gas, water and some solid materials. Compared with round steel and other solid steel, steel tube has the same flexural and torsional strength and lighter weight.

GB/T 8162 42CrMo seamless steel pipes chemical composition:

|

Grade |

C |

Si |

Mn |

Cr |

Mo |

Ni |

W |

B |

Al |

Ti |

V |

|

42CrMo |

0.38-0.45 |

0.17-0.37 |

0.50-0.80 |

0.90-1.20 |

0.15-0.25 |

|

|

|

|

|

|

GB/T 8162 42CrMo seamless steel pipes mechanical property:

|

Grade |

Tensile Strength(MPa) |

Yield Strength(MPa) |

Elongation in 2 in.(50mm) |

|

42CrMo |

1080 min |

930 min |

12% min |

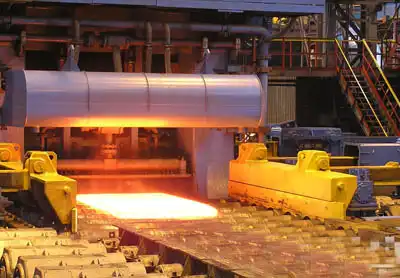

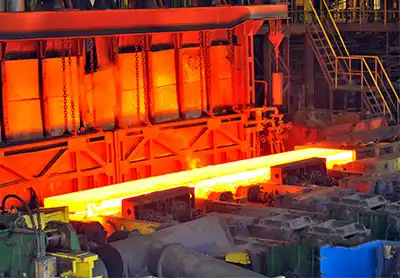

General seamless steel tube production process can be divided into cold drawing and hot rolling and cold rolling 42 crmo general than hot rolled seamless steel tube production process is complex, three-roll rolling tube billet must first, after the extrusion sizing test, if there is no response after crack on the surface of pipe have to be cut after cutting machine, cutting grow about a meter of billet. Then it enters into the annealing process, in which acidic liquid is used for pickling. During pickling, attention should be paid to whether there is a large amount of bubbling on the surface. If there is a large amount of bubbling, it means that the quality of steel tube cannot reach the corresponding standard. In appearance, cold-rolled seamless steel tubes are shorter than hot-rolled seamless steel tubes. The wall thickness of cold-rolled seamless steel tubes is generally smaller than that of hot-rolled seamless steel tubes, but the surface looks brighter than that of thick-walled seamless steel tubes without too much roughness on the surface and too much burr on the caliber.

Hot rolled 42CrMo seamless steel tube delivery state is generally hot rolled state after heat treatment for delivery. After the quality inspection, the hot-rolled seamless steel tube shall be selected by the staff strictly by hand. After the quality inspection, the surface shall be oiled, followed by several cold drawing experiments. After the 42CrMo hot-rolled treatment, the perforation experiment shall be carried out. After straightening, the device is transferred to the flaw detector for testing, and finally labeleds, arranged in specifications and placed in the warehouse.

Do you want hot rolled or cold rolled GB/T 8162 42CrMo seamless steel pipe? Please communicate with us by email.